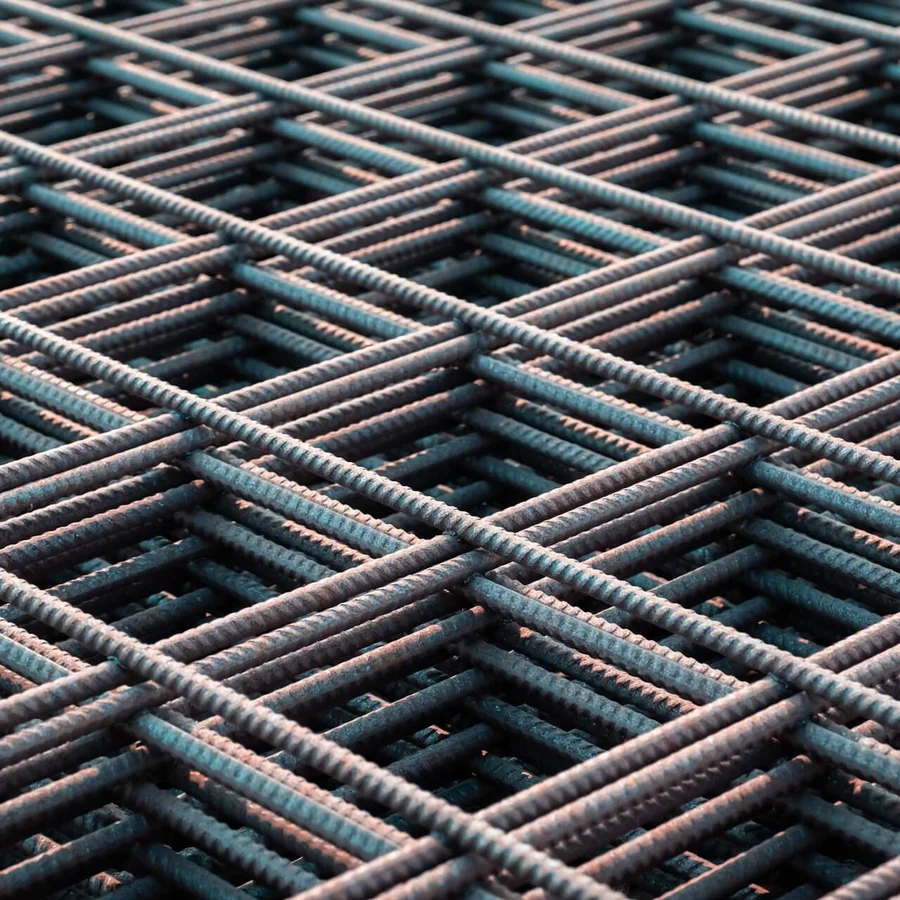

Steel Reinforcement Mesh

Steel reinforcement mesh, also known as rebar mesh or welded wire fabric, is a pre-fabricated sheet made of steel wires arranged in a grid-like pattern. Steel reinforcement mesh is used primarily in the construction industry to strengthen concrete structures and enhance their durability, stability, and load-bearing capacity. Embedded within concrete elements such as slabs, walls, columns, and foundations, rebar provides additional support and resistance against tensile forces, such as bending, shearing, and temperature changes.

Mesh reinforcement panels helps to distribute stresses evenly throughout the concrete, reducing the risk of cracking, deformation, and structural failure. It also helps to control shrinkage and cracking during the curing process, improving the overall quality and longevity of concrete structures.

Features:

High strength and good stability.

Improve bonding to concrete, minimize concrete cracking.

Flat even surface and firm structure.

Corrosion and rust resistant.

Durable and long service life.

Specifications:

Material: carbon steel or stainless steel.

Surface treatment: galvanized.

Mesh opening shape: square or rectangular.

Steel rod style: ribbed or smooth.

Diameter: 3m–40 mm.

Distance between rods: 100mm, 200mm, 300mm, 400mm or 500 mm.

Mesh sheet width: 650mm – 3800 mm.

Mesh sheet length: 850mm – 12000 mm.

Standard reinforcing mesh size: 2m× 4m, 3.6m × 2m, 4.8m× 2.4m, 6m× 2.4m.

Production Process:

1.purchase raw material and inspection

2.drawn wire to required wire diameter, and measure it by micrometer

3.welded on the machine to mesh panel

4.inspection by micrometer, vernier caliper, steel tape and laboratory testing

5.Storage and shipment

Common Applications of Reinforced Mesh:

Concrete slabs

Household shelters

Road surfaces

Walls and panels

Drains